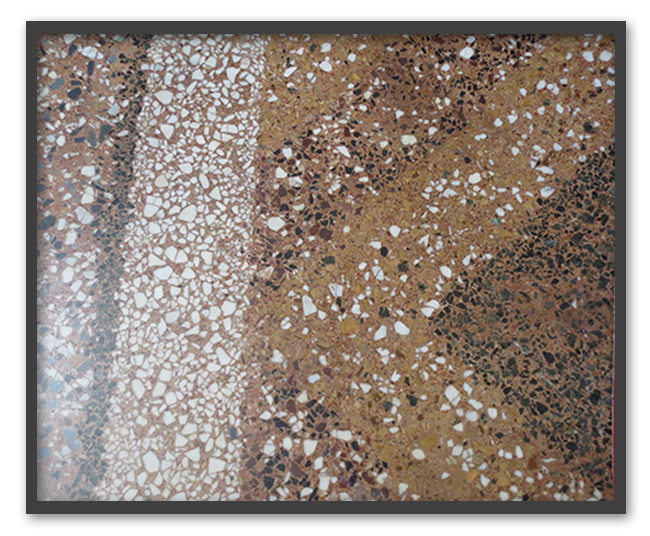

Floor decoration becomes a real art expression

Venetian terrazzo and Mosaic installation

For Asin, there are no jobs which do not require a quest for the most appropriate materials or the most particular stones. All the decorations are made on site using the technique called “sprinkle”, whereby the drawing is directly transferred onto the plastering. When the decorations are more complex, the use is envisaged of “templates” which are laid on the foundation covering; after the terrazzoe has been “sown” the templates are removed and in the areas left free, decorative details are threaded by hand and the grit is sown.

Asin is one of the few companies still able to make a floor using ancient materials like the Venetian floor with “slaked lime” binder or the famous “pastellone” floor.

When shape becomes reality

What distinguishes the Venetian terrazzo from every other floor today existing on the market is that it is fully made on site. The construction phases are manual and have substantially remained unaltered over the centuries.

On the foundation, thin sheaths of bituminous or nylon paper-felt are laid; then the base is suitably prepared with concrete and reinforced with electrically-welded mesh; after leaving to dry, the plastering is spread and then the marble grit or river pebbles are sown manually; immediately afterwards, the job is completed by rolling and beating what has been installed so far. The last phases are honing, grouting, polishing and end treatment with floor wax.

Asin carefully carries out all these procedures so as not to lose the hand-craftsmanship acquired over centuries and which distinguishes the real Venetian terrazzo from many other floors available on the market, the upshot of approximate and speedy methods.

Lime Terrazzo

Asin remains one of the few terrazzo makers to still make Venetian floors using lime.

Lime mortar and crushed pottery mixed with pottery lime, thin grit, sown marble, manual honing, grouting with cooked linseed oil and tailor’s chalk, and final oiling with raw linseed oil.

.

Cementitious binder terrazzo

Installation of a layer of base covering with cementitious binders.

Plaster covering made up of white cement and thin grit and dyeing oxides.

Manual sowing of various marbles.

Floor beating using suitable equipment and, after seasoning, mechanical honing, grouting and final polishing.

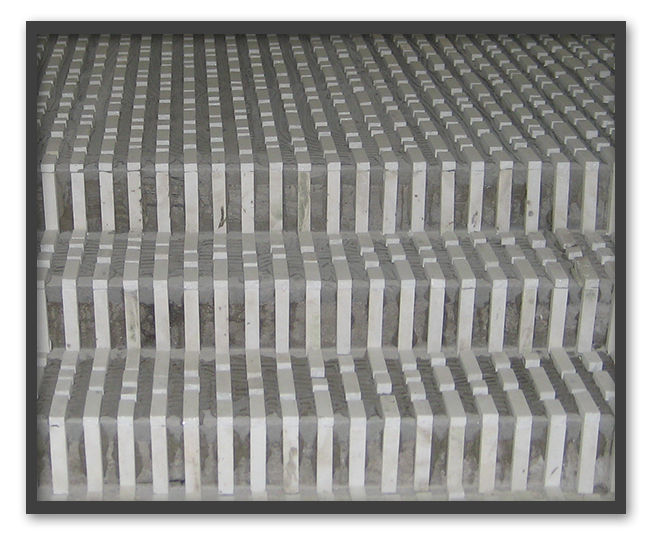

Tessera Floor

More modern version of the classic Venetian floor where the hand-cut and geometric-shaped tesserae are positioned one by one manually. A famous example of tessera floor is that designed by architect Scarpa in the Olivetti store in Piazza San Marco in Venice.

Resin Floor

Floor obtained with a mix of epoxy resin and thin marble grit of various grain sizes. Mechanical honing and final polishing.

Mosaic

Our mosaics are made entirely on site.